|

FOR '89-'93 for Dodge TURBO DIESEL 4X4s,

REPLACING THE GETRAG FIVE-SPEED WITH A

NV4500HD

Since 1996, Quad 4x4 has been retrofitting

1989-'93 Dodge Turbo Diesel pickups originally equipped with

the Getrag five-speed transmission with the newer NV4500HD

five-speed transmission that is original equipment in 1994 and

newer trucks.

Complete 4x4 NV4500HD

Conversion Kit features a brand new, current production

transmission and all required parts to replace the original

Getrag G360. |

When off-warranty 1989-'93 Dodge trucks with blown Getrags

started coming in our shop in 1996, it was obvious a simple

rebuild wasn't going to be the solution. These trucks came

with a 7 year-70,000 mile warranty which must have caused Dodge

a fortune in transmission warranty claims because nearly 75% of

these trucks we have seen had one to four transmissions replaced

under warranty. With that kind of track record, you know the

factory part just isn't up to the job. In addition, many of the

parts required were not available and those that were had a

gold-plated price tag.

Our inspection of failed Getrags revealed

that excessive heat and insufficient lubrication were causing

the transmissions to literally self destruct from bearing

failure. At that point, I started doing research on the Getrag design and service procedures, looking for possible ways

to modify it for better lubrication and cooler operation.

My research showed the basic problem of premature failure with

the gearbox was probably a combination of premature pilot bearing

failure, use, bearing preload, basic design, type of lubricant

and the power of the Turbo Diesel. We considered

installing an external oil cooler and using synthetic lubricant.

Our conclusion: while an oil cooler might prolong transmission

life, we would still see bearing failures due to the modest size

of the preloaded bearings; the use of a single tapered roller

bearing on the front of the main shaft to handle radial, lateral

and thrust loads; and drivers who would power up hills with

heavy loads in fifth gear.

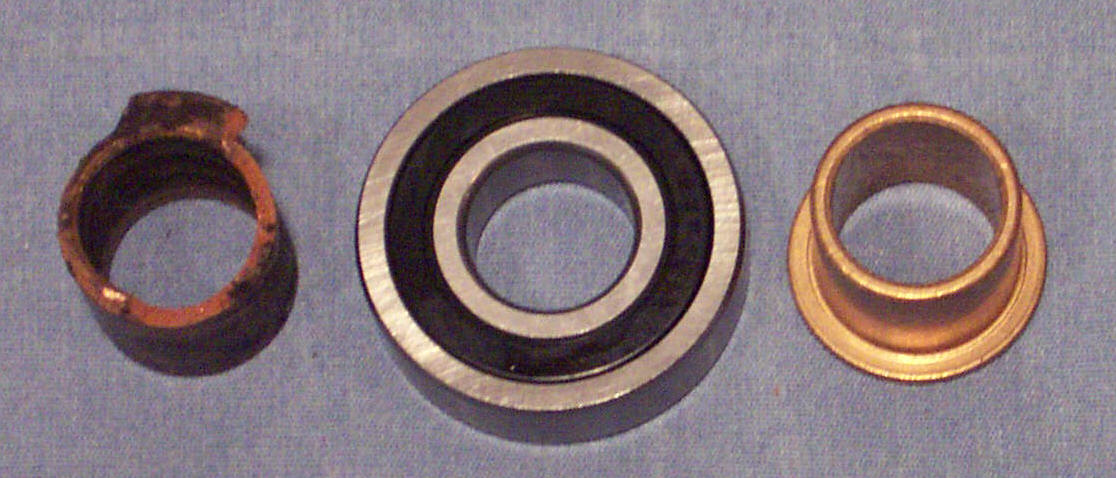

The only contributing factor to Getrag

failures that is easy to remedy is the clutch pilot bushing. Why

Dodge used a pilot bushing in the first place is a mystery, but

a simple flywheel modification that any competent machine shop

can perform permits the installation of a heavy duty, sealed

ball pilot bearing.

Broken

stock clutch pilot bushing on left only lasted 44,000 miles. It

is strongly recommended you replace the stock bushing (a new one

is shown on the right) with the heavy duty, thick wall

QU51010 sealed

ball pilot bearing (center). Flywheel modification is required. Broken

stock clutch pilot bushing on left only lasted 44,000 miles. It

is strongly recommended you replace the stock bushing (a new one

is shown on the right) with the heavy duty, thick wall

QU51010 sealed

ball pilot bearing (center). Flywheel modification is required. |

Our first thought was to install an older style four-speed with

an auxiliary overdrive or installing a medium duty truck

five-speed with adapters. These options may be viable

alternatives, but high cost and supply problems made us decide

to try the update to the NV4500 gearbox. Our first

conversion took a week and utilized an adapter plate between the

transmission and original bellhousing. Currently we are

buying brand new, semi-finished bellhousings to adapt the NV4500

transmission to the Cummins engine.

The NV4500HD is a reliable and heavy duty

transmission that is more than capable of handling the power of

the Cummins engine. Early models had problems with retaining the

fifth gear, but that has been taken care of by new mainshaft and

nut designs. It is still a current production transmission, which

means brand new units are available and affordable, plus service

parts will be readily available for years to come.

The combined length of a new 4x4 NV4500HD and bellhousing is

only 1/8" longer than a Getrag, so no driveline or crossmember

modifications are required on 4x4 trucks. There is minor

welding involved to reinforce the original transmission support

plate and to modify the transfer case shifter to bolt to the new

transmission. The weld-on pieces are included with the

conversion kit.

The 4x2 conversion is a bit more involved.

Cross member and propeller shaft modifications are necessary. We

supply steel to weld to the crossmember as part of the kit. The

4x2 conversion also comes with a new transmission mount and rear

output yoke for the transmission. Some 4x2 trucks will also need

the speedometer driven gear replaced for proper speedometer

calibration.

4x2 NV4500HD with modified crossmember installed in a 1993 W250 |

Included in all 4x4 conversions is a brand new, modified,

current production NV4500HD transmission, new bellhousing with

slave cylinder studs and pivot ball, clutch pilot bearing,

clutch release bearing, transfer case input seal, transfer case

adapter gaskets, adjustable transfer case linkage, Syntorq 75w85

synthetic gear lube for the transmission, transmission shifter,

new floor plate, heavy duty transmission mount, made in the USA

grade 8 hardware, 100 minute installation video, miscellaneous

small parts, shop supplies, etc.. The primary components of the

4x2 kit are the same except of course the transmission is a 4x2

unit.

(left) Getrag G360. (right)

NV4500HD. Larger case of NV4500HD requires a new bellhousing to

retrofit first generation Dodge trucks. |

The actual time required for an amateur

mechanic to install the new NV4500, is probably around 15 hours. The conversion starts with the removal of seat and

shifters. The new shift tower is farther back, so once the

carpet is removed, a hole is cut in the floor to provide

clearance for the new shift tower. Next, remove the drive

shafts, disconnect the wiring, remove the transfer case, crossmember, transmission, bellhousing, and clutch components.

The clutch assembly is a long-lasting (but somewhat "grabby" on

take-ff) 13" Sachs/Borg and Beck unit which can almost always be

reused, unless it has been subject to abuse or high (200,000)

mileage. If required, a brand new Sachs/Borg and Beck

assembly is available as are a number of 12.4" and 13"

South Bend performance clutches. The modified flywheel

and ball clutch pilot bearing are installed after checking the

rear crankshaft seal for leakage. Next is clutch assembly

installation, then the new bellhousing and transmission.

The original 4x4 crossmember is reused with the addition of a

new heavy duty transmission mount. After the new transfer

case input seal is installed, the transfer case is bolted to the

transmission. One of our two styles of transfer case

linkages is then installed, depending upon the year of the

truck. With our kit, drive shaft modifications are not

required, so finishing the underbody portion of the conversion

requires simply replacing the remaining components and pumping

the lubricants. The truck is then lowered for finishing

the interior portion of the conversion which requires installing

the new floor plate and shifter, relocating the transmission

shifter boot, replacing the carpet, seat, and transfer case

boot."

First generation 1989-1993 Dodge turbo-diesel trucks have steel

shell rear crankshaft seal pressed into an aluminum seal

housing. Over time, the different expansion and contraction

rates of the two metals will compress the seal shell. When this

happens, engine oil starts to seep between the seal and

seal housing. Replace this original seal before installing

the NV4500HD. The

QK6000 crankshaft seal

kit includes the new design, Teflon lip seal with rubber sealing

rings, installation tool, and video guide. |

The forward gear ratios of the current NV4500HD are

slightly wider than the original Getrag. Reverse gear is slightly

faster. (Gear Ratio Chart). Given

the relatively narrow rpm band of the Cummins engine, does the

wider ratio adversely affect performance? That was one of

my main concerns when we started doing these conversions, but

every customer that has commented on the gear splits tells me

that they have a better spacing than the original Getrag.

Everyone seems to like the lower first gear and the higher

overdrive too. As a rule, NV4500's shift a lot nicer than

the old Getrags.

The bottom line on retrofitting the NV4500

into '89-'93 models is that for about the same price as most

Getrags can be pulled and rebuilt, the customer gets a stronger,

more reliable, and easier shifting transmission. |